Wear Resistant Chrome Bimetal Steel Plate with Chrome Hardfacing Layer

Wear Resistant Chrome Bimetal Steel Plates with Chrome Hardfacing Layer are bi-metallic plates combining an adaptable steel base with a highly alloyed wear resistant hardface. The low carbon steel base plate allows the product to be welded, bolted or studded to existing structures, while the surface coating provides excellent wear resistance.

Wear Resistant Chrome Bimetal Steel Plate with Chrome Hardfacing Layer

Wear Resistant Chrome Bimetal Steel Plates with Chrome Hardfacing Layer are bi-metallic plates combining an adaptable steel base with a highly alloyed wear resistant hardface. The low carbon steel base plate allows the product to be welded, bolted or studded to existing structures, while the surface coating provides excellent wear resistance.

Key features

Good corrosion resistance due to high Chrome content

Good metal to metal wear resistance

Good Metal to Metal resistance

Very small heat-affected zone

Good heat resistance

Hardness and composition designed to suit the application

manufacturing technique

Product feature:Low cost, Consistent quality hardface,High carbide content,Excellent wear

Resistance

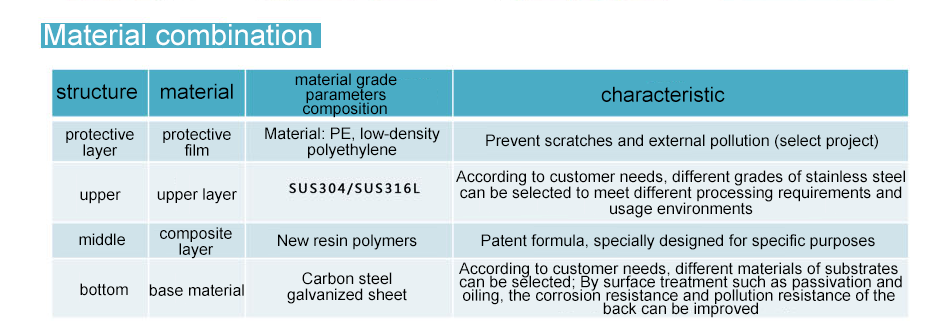

1. Corruption: The inner layer of the composite plate uses SUS304 food-grade stainless steel, which has high corrosion resistance. The outer layer uses hot-dip galvanized steel plate. After installing the finished product, add corruption coatings, which has multiple corrosion resistance.

2. High strength: B has high strength, because galvanized steel plates have good internal and external pressure.

3. The ideal mechanical structure: The protruding part of the double-forming water tank from the perspective of mechanics uses the sphere.

4. Do not leakage: Unique structural design, no welding combination on site. High strength and good sealing, preventing secondary pollution of water quality.

5. Easy to construction: Users can propose the length, width, and height of the water tank according to the design needs (the standard sector is 1m*1m, 1m*0.5m) arbitrarily, and there is no special requirements for the installation site, especially for land burial and large water tanks. Seen in the fire water tank, and can provide insulation (polyurethane foam insulation, rock wool , rubber or plastic insulation) services.

6. Concrete foundation Requirements: requires the height difference for the plane<5mm, The distance between each beam is 100cm, the height> 50cm.

FAQ:

Q:How much do you support MOQ?What kind of trade do you support?

A:We support 1cubic meters MOQ.We support all forms of trade,for example EXW FOB CIP DAP DDP and so on.

Q:What is the lead time?Can you offer the assemble?

A:We will deliver the goods in 5-15 days according to your quantity.We support engineers to travel to your country for installation, and can also remotely guide local workers to install.

Q:Do you support the samples? What is your shipping method?

A:We support the production of samples, and you need to pay for the samples and freight. For small and light goods, we will use fedex, UPS, etc., and for heavy goods, we will send them by sea.