Bimetal hardfacing wear plates

Bimetal hardfacing wear plates are composite materials used in various industries to protect equipment and machinery from wear and abrasion.

Bimetal Composite Plate

Bimetal hardfacing wear plates

Bimetal hardfacing wear plates are composite materials used in various industries to protect equipment and machinery from wear and abrasion.

product description:

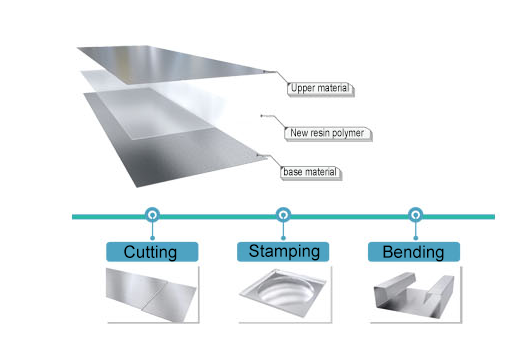

Dual-metal composite materials can be arbitrarily used as thinner metals such as thin stainless steel, copper, aluminum, etc., and use thicker galvanized plates as substrates (metal materials that can also be used with other materials). Dual-metal materials compounded with new resin polymers with physical machinery. Dual-metal composite materials technology can give full play to the advantages of each group of metal materials, realize the optimal allocation of material resources, save the use of precious metal materials, and achieve performance requirements that a single metal cannot meet. Take stainless steel composite board as an example. The substrate-like carbon steel and galvanized plate have good mechanical properties. The panel has a good corrosion resistance with stainless steel (SUS304/SUS316L), which has a wide range of applications, economic benefits and social effects. Development of stainless steel composite materials has always been a high-tech project actively supported and advocated by the Ministry of Science and Technology.

Advantages:

-The high hardness and high abrasionability, can resist repeated wear and impact.

-The high corrosion resistance and can be used for a long time in harsh environments.

-The good welding performance and processability can meet the needs of different shapes and sizes.

-In a longer service life for the equipment, reducing the maintenance time and cost of stopping the maintenance.

In general, dual metal composite wear-resistant plates are a high-performance wear-resistant material that can significantly improve the service life and performance of the equipment, and is widely used in industrial fields that need to resist abrasion and corrosion resistance.

|

Structure |

Material |

Material/parameter/ingredients |

characteristic |

|

Protective layer |

Protective film |

Material: PE, low-density polyethylene |

Prevent scratching and external pollution (select items) |

|

Upper layer |

Surface material |

SUS304/SUS316L |

According to customer needs, you can choose stainless steel with different brands to meet different processing requirements and use environment |

|

Middle |

Composite layer |

New resin polymer |

Patent formula, directional special production |

|

Lower layer |

Substrate |

Carbon steel galvanized plate |

According to customer needs, you can choose a substrate with different materials; through the surface treatment of passivation, oil coating, improve the corrosion resistance of the back and pollution resistance |

Manufacturing Process

Pre-production: All raw materials are food grade.

Production:Each panel are in strict quality control and make sure each panel flawless.

After-Production:All panels completion,there are second quality control team randomly picks some for weight and strength inspection.

Finally,all panels will be classified and stocked temporarily according to panel thickness.

FAQ

Q:Are you a factory or a trading company? What kind of payment method do you support?

A:We are a factory, we support many payment methods L/C T/T credit card PayPal and so on.

Q:Do you have your own R&D team? What if something goes wrong with the product?

A:Yes, we have a professional R & D and qc team, if there is a problem with the product, we will immediately send our overseas engineers to help you solve the problem

Q. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their owncosts incurred during this period and the spreads

Q. How can I get a quotation from you ?

You can leave us message, and we wil reply every message in time. Or we may talk on line by Trademanager And you can alsofind our contact information on contact page.